Dear MOTO GUZZI rider ,

thank you for your interest in our MOTO GUZZI – engine programme .

In the different dyno sheets you always see V-Kit or Ventiltriebskit (valve train kit) , Brennraum (combustion chamber) and Doppelzündung (dual ignition). After reading this text you will exactly know what is meant.

We do not limit our work to simple bolt-on accessories or engine tuning parts. We have noticed though, that the dimensional tolerances on bikes with Italian parts seem to depend on the fitness of the mechanic ;-). Some people assume a direct connection between the quantity of Chianti during lunch and product quality. In any case, lots or riding difficulties can be avoided by choosing the exact part in the first place, and if necessary tidy remachining.

The DYNOTEC crew would like to explain to you in this text, why we are a great address for your MOTO GUZZI:

Many MOTO GUZZI riders have a fixed conception of what engine modifications are likely. Looking from the outside, it is not possible to detect the cost of repairs when stripping an engine, particularly a high performance unit.

Therefore we offer the following program:1

- Engine strip down and measurement

- Calculation of repair cost

- Budget check and fixing of optimum measurements.

Spend the day with us in our workshop and rebuild the engine, gearbox and Kardan together. During this time you can ride our test bikes to give you an idea of the result of the different stages. Also you can request example invoices by e-mail. Just tell us your engine type and the Torque and Power you require.

You may even rebuild the engine yourself or ask a dealer to do it, just send the parts to us. When we’ve checked everything we will call you to discuss your requirements, do the work and then send all the parts back ready to fit in a kit.

Think about this!

The most important thing for engine optimization is for it to operate from low-down upward. The crankshaft should be well prepared for the forces that come with higher revs. (Bear in mind that many Guzzis now sport lots of miles). Accurate axial play and a perfect balancer are the prerequisites for long engine life. The newer the models are the less important the balancing becomes. Balancing must be done to T3 models and Lemans 2 and older.

Crankshaft electronically fine-balancing

First the pistons are bought accurately at the same weight. The conrods are weighed out and adapted according to their rotary and osscilating masses. After this, the master weight for the crankshaft is calculated and the crankshaft made. This master weight is then balanced, any errors being compensated for. This procedure protects small tolerances and supplies the best automatic result. To do this we leave our crankshafts in the internal combustion engine laboratory of the professional school for technique in Mannheim, they have the highest precision and state of the art machinery.

DYNOTEC machined crankshafts may be found in sidecar engines with more than 200,000 km running performance, and in the engines of DNL Ducati Corse (Edwin Weibel, Christer Lindholm). The Guzzilla utilises our own crankshaft with a 82mm stroke and a 48mm front bearing (10 mm bigger that original).

Valve train kit ( Ventiltriebskit ) 7906 or other numbers

The original camshaft kit of all MOTO GUZZI of models were the main engine problem :

The original camshaft kit of all MOTO GUZZI of models were the main engine problem :

- No valve rotation

- Brocken springs

- Damaged valves on high revs ( missing a gear for example )

- Pitting on cam followers

- Sharp cams, surface damaged

Because of all this reasons we decided to sell only complete kits that solve all the problems. We have 16 different camshaft kits ( cam, springs, steel top collar, cam followers ) for any type of a Guzzi engine you want.

The cam followers are conical into the large MOTO GUZZI engines and the cams are flat. The follower runs on one edge of the cam and sustains pitting. Then the camshaft surface gets destroyed and the kinetics of the valve impulse are gone. Italian aftermarket cams never work exactly, their kinetics were never calculated and they never give you the cam timing, the spring hardness and lift, or any information about the distance the valves travel. They sell torque cams and race cams??? But the cam timing depends on the capacity of the engine and the diameter of valves and porting.

For example : a torque cam in a 850 T3 engine is a high-end cam for the Le Mans 4. !!!

There is no ramp on any cam for a Guzzi (original and aftermarket). But the ramp is very important for a push rod engine to give a little pressure on the valve train before the cam accelerates. Then when the cam does accelerate, it should be very slowly. On the inlet it means less turbulence but for the exhaust, it means the flame burns through a 2 mm space between valve seat and valve because the valve opens to slow between 2 and 6 mm.

Dynotec – high-capacity valve springs are from German production of the design, as they were used before the era of the pneumatic systems in the formula 1. They are so stable that they can be distanced 1 mm before block. With an overturner the interior spring blocks, holds the valve and cannot damage the piston modified by the combustion chamber internal message. The top collar high-strength steel prevents the valve from falling into the cellar. They have the three-way firmness of the standard aluminium sections and they always hold the spring distance exactly.

Dynotec – high-capacity valve springs are from German production of the design, as they were used before the era of the pneumatic systems in the formula 1. They are so stable that they can be distanced 1 mm before block. With an overturner the interior spring blocks, holds the valve and cannot damage the piston modified by the combustion chamber internal message. The top collar high-strength steel prevents the valve from falling into the cellar. They have the three-way firmness of the standard aluminium sections and they always hold the spring distance exactly.

Never more damaged valves by short over turners !!!!!!

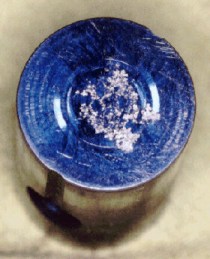

At the casting of the rocker arm (picture left) on the valve shaft you can see that the valve does not turn and thus, the contact area, valve shaft and valve guide wears unequally. By not having rotation, the valve-seat area also wears unequally (picture below right), which will lead inevitably to a leaky valve seat, and finally, to overheating and burning the valve through or and the valve profile.

At the casting of the rocker arm (picture left) on the valve shaft you can see that the valve does not turn and thus, the contact area, valve shaft and valve guide wears unequally. By not having rotation, the valve-seat area also wears unequally (picture below right), which will lead inevitably to a leaky valve seat, and finally, to overheating and burning the valve through or and the valve profile.

Crucial advantages also arise for the lead free engines as a result of Dynotec Ventilfederkits: The valve springs cause a rotation of the valve in operation, which stems the ends of the valve and protects the valve seats from premature wear. We tested different cam profiles in many engines on the test bed and while riding.The most recommendable versions are documented in a table. The Camshaft Kits work so well that they are always copied. But remember: An optimum camshaft is manufactured as a copy of the original cam, not as copy of the copy!!Never buy a cam without springs and exact spring adjustment dimensions

Combustion chamber work ( Brennraumaktion )In order to eliminate the tolerances mentioned above and in the combustion chamber, we have developed the combustion chamber internal message in connection with the respective valve impulse kit. The valve seats are machined in such a way, as is necessary for each camshaft. Then the pistons are machined with the exact valve cutouts.The combustion volume will meter out and brought on the compression optimal for the selected motor type. This handling is in the meantime in the folder of many providers. But the crucial “which” and “how much” results from our decades of experience with the large MOTO GUZZI – engines is continually kept up to date.We started in 1984 with racing engines and all this work is the result of this long-term research and development.The assembly of a camshaft kit and a reworked combustion chamber can be done in 2-3 days, giving lots more riding time.Camshaft kit, combustion chamber work and carbon coated valves are all included in the ready to install kit we offer for every engine. You send us your heads, pistons, cylinders and the old camshafts. You also can have a drawing showing how we will machine your parts.

Clutch facilitate and balanceThe clutches have a weight, which would be ok for a small car. But since we do not have to set tonnes of weight in motion, it is advisable to lighten and balance the clutch. The single-disc clutches work well so far. They are however for the strongest two-valve – engines, for engines with lots of low-down power. For the torque monsters we have special Sachs Plates that manage the 150 Nm of the Guzzilla easy and they are easy to handle even in traffic jams. The flywheel and starter ring are balanced individually, so that parts can be changed easily.

Lead-free driving ( Bleifrei fahren )Camshaft kits for lead free engines are available, after detailed material testing and detailed practice tests from LM 3 on. Only the original valves are much too soft. We use specially made carbon-coated Cosworth valves in connection with new guides in absolute lead free quality. So we can offer a technically perfect, low-priced lead free change.

First KM and Lambda Tuning for the rebuild engineEvery customer get back all their old parts, a basic carb or eprom setup and a recommendation on how to deal with the optimized bike. After approximately 500-1000 km it will be necessary to make a Lambda check by riding on the road where the bike lives ;-). We go through the new adjustment together with the engine on the test stand, and we show you the result. The basic kits are a 95% setup but it is better to check the Lambda after running. Additionally: A badly setup motorcycle drinks more, harms the wallet and the environment.

GearboxWith the diagonally interlocked series transmission 1st and 2nd gear- wheel is the shaft and 3rd and 4th gear is pressed onto the shaft. The axial forces press the 3rd+4th gear to the side, the bearings at the end of the shaft break and the needles are flying around in the gearbox. Those pressing apart pull and as consequence the needle bearing 5. is destroyed. These sections then fall into the transmission and all hell breaks loose. It is advisable to develop the transmission with the engine, take it apart again and drill the waves and top pin. This internal work is economical and recommendable, since expensive transmission parts can protect from premature failure.

Final drive/cardanThe cardan actually failed without constructional defects and required only one examination of the contact reflection and the taper roller bearings. The Kardan is completely divided, exchanged those taper roller bearings with more stable items and dissociated correctly. The life span increases by 100 %.

Send us your questions by mail and ask after a programm for your Moto Guzzi